It needs labor to operate so the raw material is put into the pyrolysis reactor by the labor. Wood residues were pyrolysed in a cylindrical batch reactor at temperatures 300-350 400-450 and 500-5500C and the organic were characterised using a gas chromatograph GC fitted with a flame ionisation detector FID.

Continuous Or Batch Type Plastic Pyrolysis Plant

Safety Procedure Regulation of Batch Pyrolysis Process 1.

. This also applies to batch-based reactor concepts. The yield of TPO was optimized with reaction temperature to produce high quantity of gaseous outputs. In slow pyrolysis the rate of heating is very less around 57 Cmin and possesses a longer residence time of more than 1 h.

The process is often used in the semiconductor industry to produce thin films. It can work continuously for 24 hours a day. The batch type pyrolysis plant doesnt need pre-treatment devices and the raw materials can be put into the reactor directly.

The reactor has 20. Working Process of Batch Pyrolysis Plant For batch pyrolysis system you dont need to buy much pre-treatment equipment. 1 feeding system where the raw material is typically heated and melted with the liquid outflow being fed into the reactor 2 a PVC cracking at 350C is required for feedstocks containing PVC 40 3 pyrolysis reactor operating at temperatures between 350 and 650C 18 and 4 a.

This plant can handle these raw materials such as waste tires plastics rubber oil sludge. The aim of this study is to model a batch reactor to be used for plastic pyrolysis. Batch Type Pyrolysis Plant.

The BLJ-06 6 TD BLJ-10 8-10 TD batch operating pyrolysis plant can handle these raw materials such as waste tires plastics rubber oil sludge and the final products are fuel oil carbon black steel wire for tires. Feed waste materials into reactor by manual and make reactor rotate clockwise 04-08rmin. Longer service life and safer Continuously operating reactors such as Rotary and Auger reactors have been covering a wide range of industrial applications for decades.

To bridge these gaps a pyrolysis batch reactor was designed and fabricated in the present investigation with an overall dimension of 400 X 200 X 458 cm and handling capacity of 10 kgs per cycle. After feeding heat the reactor to a certain working temperature and then the. Go to the project directory cd fcic-pyrolysis Run a batch reactor model for a single feedstock python srcrun_batch_singlepy Run a batch reactor model for all the feedstocks and compare results python srcrun_batch_allpy Determine the biomass composition for a single.

The manifold separates the heavy oil gas and. Alcohols acids furans phenols aldehydes and ketones. Examples of running the code in a terminal are given below.

However there is no need to wait for cooling down the reactor in a continuous pyrolysis unit. Just put the raw material into the pyrolysis reactor manually or with a feeder. Continuous Pyrolysis Reactor Working Method As mentioned for the batch pyrolysis system you need to pre-heat first.

Working Process of Batch Pyrolysis Plant. The final products are pyrolysis oil carbon black steel wire for tires. Several types of reactors are commonly used for the pyrolysis of SWs.

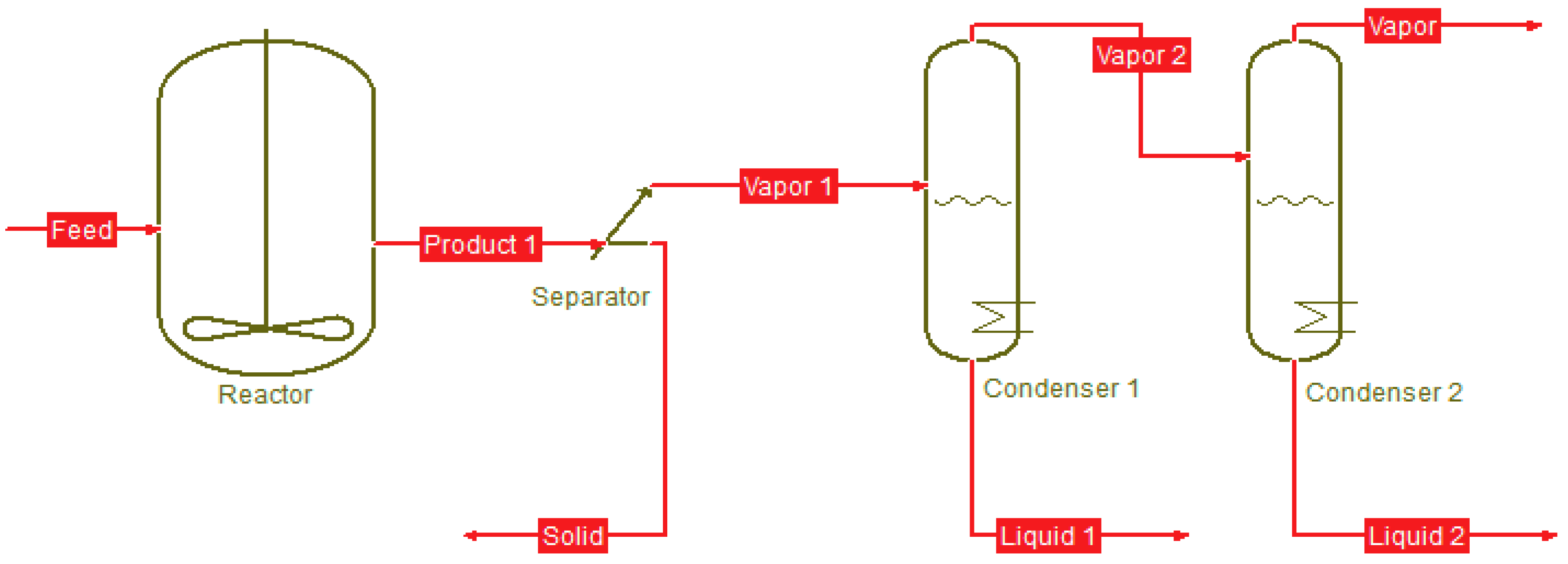

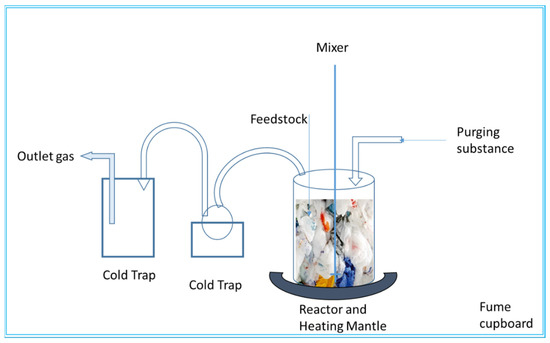

Seal the feeding inlet. The pyrolysis process was carried out in a high-pressure batch reactor described previously It includes a 375-L 1 gal size reactor a condenser cooled by a waterethylene glycol jacket maintained at about 10 C a receiving vessel for liquid product collection and a water displacement setup to determine gas quantity. Most of the pyrolysis reactor technologies consist of three main sections.

We are here to bring together China factories that sup. However the different pyrolysis temperature zones of coal and biomass seriously affect the realization of these effects. A distinction is made between batch and continuous filling and processing modes which in turn significantly determine the reactor design.

The reactors are as follows. The most notable compounds in the wood vinegar and tar were. The main goal was to perform a comprehensive study on the depolymerisation of PS thereby investigating the effect of reactor type catalyst arrangement feed to catalyst ratio and residence time on the yields of oil and styrene monomer SM.

They have been tried and tested and are state-of-the-art. Working process of Beston batching pyrolysis plant. Each reactor differs from the others by its working principle advantages and an experimental setup Bridgwater and Peacocke 2000.

In this respect the present work deals with the thermo-catalytic pyrolysis of PS in batch and semi-batch reactor setups. US20060163053A1 - Batch pyrolysis system - Google Patents Disclosed is a scaleable pyrolysis system for batch processing of waste vehicle tires and. China manufacturing industries are full of strong and consistent exporters.

Batch-based semi-continuous tire pyrolysis concept. The thermochemical decomposition process pyrolysis takes place in a reactor reaction zone. The reactor will be slowly.

Heat the reactor by using coal charcoal fuel gas wood etc. Consequently four experiments with different heating and cooling cycles are done using an empty pyrolysis batch. After pyrolysis you need to wait to cool down and then discharge the carbon black.

Light the combustion chamber before feeding materials to preheat the pyrolysis reactor which is better for improving. This batch type does not need pre-treatment devices and the raw materials can be put into the reactor directly. Small pilot scale batch pyrolysis reactor was commissioned and used for the conversion of plastic waste into liquid oil and char Fig.

Sourcing Guide for Batch Type Pyrolysis Reactor. Send 1-2 ton materials to the platform of feeding. When the temperature of the pyrolysis reactor reaches 200 degrees the oil gas appears and the 280 degrees to 350 degrees is the biggest oil yield rate interval.

Stainless Steel Batch Reactor Unit Used For Pyrolysis Download Scientific Diagram

Batch Pyrolysis Reactor Used For Objective 2 The Various Components In Download Scientific Diagram

Semi Batch Pyrolysis Reaktor Adapted From Reference Erliyanti Et Al Download Scientific Diagram

Batch Pyrolysis Plant For Sale Handling Capacity Of 6 10t D

The Diagram Of Pyrolysis Apparatus Used In This Work 1 Nitrogen Tube Download Scientific Diagram

Pilot Scale Batch Pyrolysis Reactor Download Scientific Diagram

Stage I Pyrolysis Reactor Batch And Pyrolysis Vapour Condensation Download Scientific Diagram

Schematic Of The Batch Pyrolysis Reactor Download Scientific Diagram

Processes Free Full Text Simulation Of Batch Slow Pyrolysis Of Biomass Materials Using The Process Flow Diagram Coco Simulator Html

Batch Operating Pyrolysis Plant Available In The Market

Safety Procedure Regulation Of Batch Pyrolysis Process Beston Pyrolysis Plant

Schematic Diagram Of Pyrolysis Batch Reactor 1 Steel Cylinder Download Scientific Diagram

Processes Free Full Text Recent Advances On Waste Plastic Thermal Pyrolysis A Critical Overview Html

Pyrolysis Reactor An Overview Sciencedirect Topics

Design Fabrication And Performance Test Of A Fixed Bed Batch Type Pyrolysis Plant With Scrap Tire In Bangladesh Sciencedirect

Batch Apparatus For Plastic Biomass Co Pyrolysis 1 Reactor 2 Pid Download Scientific Diagram

Batch Pyrolysis Reactor Used For Objective 2 The Various Components In Download Scientific Diagram

The Construction Of Pyrolysis Gasifi Cation Batch Reactor Download Scientific Diagram